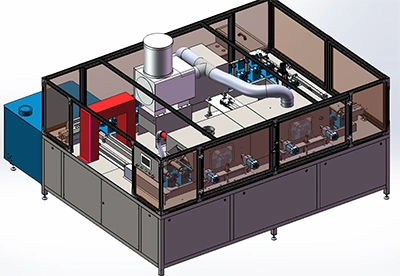

Tunnel washer for motor shafts is built for cleaning motor shafts and similar components. It integrates multiple subsystems to provide intelligent control across the entire process, from conveying and demagnetization to washing and drying, making it well-suited for precision cleaning in motor manufacturing and machining industries.

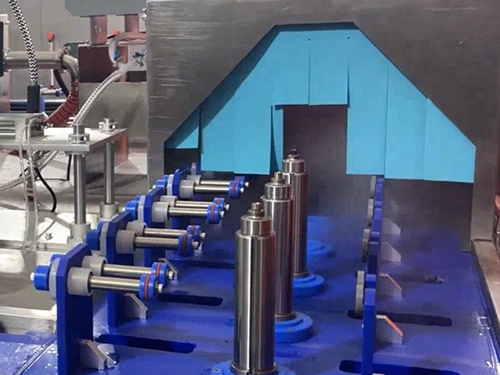

Motor shafts are manually loaded into the system, which automatically initiates the conveyor. Components sequentially undergo spray washing, steam cleaning, cold-air blow-off, and hot-air drying before reaching the unloading platform, where they are manually removed to complete the cycle.

| Applicable parts | Motor shaft (diameter 20-150mm, length 500-1500mm) |

| Cleaning efficiency | 5-10min/pc (adjustable depending on the degree of oil contamination) |

| Steam temperature | 150-200℃ |

| Sprinkler pressure | 50-100bar |

| Demagnetization | ≥3000 oersted |

| Drying temperature | 50-80℃ |

| Power supply | 380V/50Hz |

| Total power | 100-180kW (depending on configurations) |

| Water consumption | 200-500L/h (including water for steam) |

| Compressed air | Air pressure 0.6-0.8MPa, Air flow 10-15m³/h |

We’re happy to answer your questions. Send us your request and we’ll contact you soon.

Yes. Tunnel washer integrates five core stages – conveying, washing, drying, and wastewater treatment. Shafts enter via conveyor, undergo demagnetization, multi-stage washing, blow-off, and drying, exiting clean and dry for assembly.