- Home

- Applications

- Industrial Manufacturing

Industrial Manufacturing

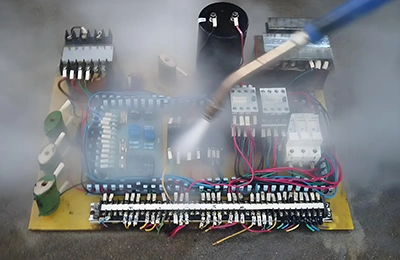

Rapid removal of stubborn contaminants such as plastic residues and mold release agents from the surfaces of injection and stamping molds.

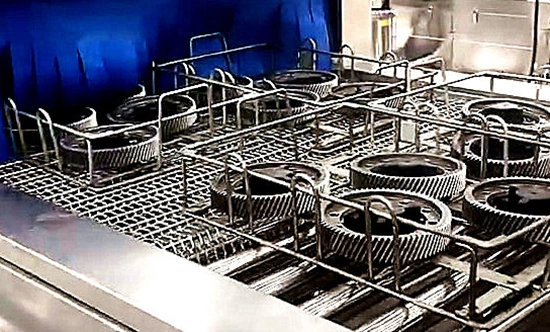

Industrial Tunnel Washing Machine (Tunnel Washer)

Tunnel washer for gears is designed to meet the strict cleanliness standards required for modern automotive gears.

Tunnel washer for motor shafts is built for cleaning motor shafts and similar components.

The automatic crate washing machine is specifically engineered to clean crates, effectively removing oil, dust, grease, and other residues that can accumulate during use.

The automatic tray washing machine is specifically engineered to remove oil, dust, grease, and other debris from crates and trays, ensuring they remain clean and hygienic for reuse.

Dedicated to manufacturing reliable and customized industrial cleaning equipment and offering OEM/ODM services to your needs.