The automatic tray washing machine is specifically engineered to remove oil, dust, grease, and other debris from plastic trays, ensuring they remain clean and hygienic for reuse. Designed for logistics, warehousing, food processing, and manufacturing environments, the tray washing machine offers a reliable solution to maintain product quality and operational standards. With a cleaning capacity of 100–150 trays per hour, the machine improves efficiency by 3–5 times compared to manual washing, significantly reducing labor intensity and water waste.

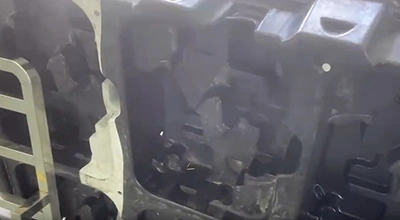

Before cleaning

Before cleaning

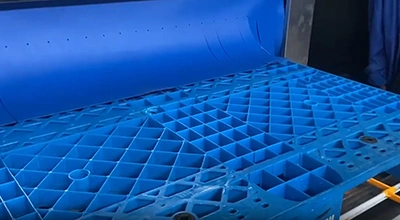

After cleaning

After cleaning

Before cleaning

Before cleaning

After cleaning

After cleaning

| Machine dimensions | 9100×2660×1745mm |

| Cleaning efficiency | 100-150pcs/hour (conveying speed 1-10m/min adjustable) |

| Water consumption | 500L/h |

| Cleaning tank capacity | 360L |

| Water pump | Washing zone 1/3: 7.5kW (Nanfang stainless steel high pressure pump, 100℃ temperature resistant, pressure ≥0.6MPa) Washing zone 2: 18.5kW (high pressure centrifugal pump) |

| Drying system | Air knife zone: 2.2kW×2 cooling air blowers + 5.5kW×2 air pump Heating zone: 2.2kW×2 high temperature fans + 38kW heating tube (air knife design) |

| Control system | Mitsubishi PLC + touch screen, supporting automatic water feeding, automatic temperature control, and fault alarm |

| Total power | 146kW (full heating) |

| Power supply | 380V/50Hz |

| Applicable tray size | Max. size: 105.5×100×20cm Min. size: 100×45×14.5cm |

| Number of operators | 2 persons |

We’re happy to answer your questions. Send us your request and we’ll contact you soon.

The multi-stage system first uses high-pressure spray to remove heavy grease, then recirculated water for rinsing. 18.5KW pumps ensure 360° coverage, while a final 7.5KW fresh water rinse eliminates residual contaminants, guaranteeing thorough cleanliness.